-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

Energy from sludge

Thermodynamic modelling of energy recovery options from digestate at wastewater treatment plants

Researcher: Dr. Karla Dussan

Summary

Funder |

Environmental Protection Agency Ireland Grant 2014-RE-DS-3 |

Starting date |

11/05/2015 |

Finishing date |

11/05/2016 |

Summary and objectives |

This work proposes to build a thermodynamic model for all sub-processes in the recovery of energy by thermochemical means from AD digestate at wastewater treatment plants. The model will include balance submodels for: (1) anaerobic digestion (simplified), (2) digestate pre-treatment and/or drying, (3) energy conversion via (3a) combustion, (3b) gasification or (3c) pyrolysis, (4) energy integration with other WWT processes, (5) air emissions control, (6) waste product handling, (7) recovery of valuable non-energy resources, and (8) subsequent production of (8a) heat, (8b) electricity and/or (8c) fuel. The work will not focus on the use of energy recovery for domestic wastewater treatment systems (DWWTS), due to the small size of these systems and the impracticality of implementing energy recovery. Objectives To review and assess the technical feasibility of thermochemical processes for energy recovery from AD digestate:

|

Projected research outputs |

|

Conferences proceedings |

K Dussan, Q Yang, X Zhan, RFD Monaghan. Thermodynamic evaluation of anaerobic digestion and integrated gasification for waste management and energy production within wastewater treatment plants. 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, June 2016 K Dussan, Q Yang, X Zhan, RFD Monaghan. Energy optimisation of waste gasification within wastewater treatment plants. 6th International Conference on Engineering for Waste and Biomass Valorisation, Albi, France, May 2016 Yang Q, Dussan K, Monaghan RFD, Zhan X. Energy recovery from thermal treatment of dewatered sludge in wastewater treatment plants. 1st IWA Resource Recovery Conference, Ghent, Belgium Aug-Sep, 2015 |

Journal publications |

Thermodynamic Modelling of Energy Recovery Options from Digestate at Wastewater Treatment Plants. K Dussan, RFD Monaghan. 2017. Environmental Protection Agency of Ireland, Report Number 2016 Integrated Thermal Conversion and Anaerobic Digestion for Sludge Management in Wastewater Treatment Plants. K Dussan, RFD Monaghan. 2017. Waste and Biomass Valorization. DOI: 10.1007/s12649-016-9812-x Energy recovery from thermal treatment of dewatered sludge in wastewater treatment plants. Q Yang, K Dussan, RFD Monaghan, X Zhan. 2016. Water Science & Technology. 2016. DOI: 10.2166/wst.2016.251 |

Links |

Why using thermal conversion for sludge management?

Nearly 55,000 tons of sewage sludge are generated every year in Ireland (1). Management of this waste (dewatering, drying, transportation, disposal) consumes a significant amount of energy that affects negatively the environmental impact of wastewater treatment. Transportation to disposal site (landfilling) can increment over 15% the fossil energy used by the treatment operations.

Currently, only 27% of the wastewater treatment facilities treat sewage sludge through anaerobic digestion (2). This biological process converts 30-60% of the organic material in sewage sludge producing biogas. Biogas is a renewable green fuel that can fuel the operations of the wastewater treatment facility. However, this process does not eliminate sludge completely.

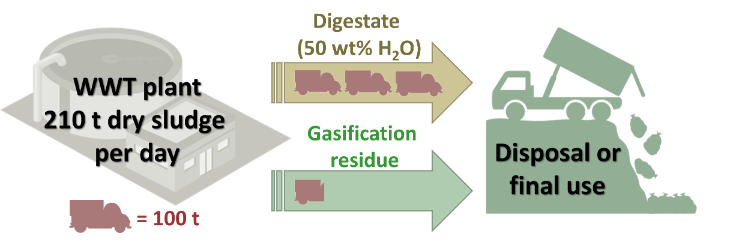

In a typical wastewater treatment plant generating 210 tons of dry sewage sludge, over 300 tons of wet digestate (50% dry matter) need to be transported every day to disposal or final use site.

Thermal conversion of sludge and digestates offer an attractive alternative that offers two products: dry and reduced inorganic waste and energy! In the scenario considered above, less than 80 tons of waste will require transportation after thermal conversion, over 70% savings in energy spent in sludge management. At the same time, the wastewater treatment facility would become energy-independent, and even an energy generation site.

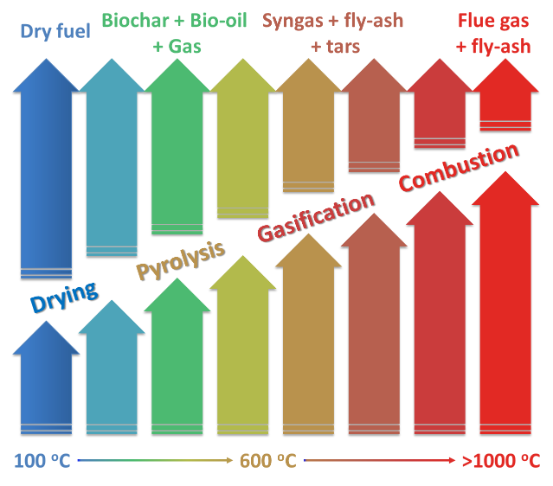

What are the advantages of technologies such as combustion, pyrolysis and gasification?

- Energy efficient processes: These technologies offer diverse and flexible alternatives adaptable to different necessities of energy consumption and process scale.

- Managing hazardous wastes: Toxic materials and heavy metals commonly found in wastes can be trapped in inert wastes that can later be used in industrial processes or disposed of in a cheaper and more environmental way.

- Reduction of the environmental impact: By generating energy from wastes, the carbon footprint of wastewater treatment is decreased. Likewise, the final waste is an stabilised and inodorous material that upon environmental guidelines, poses no threat to water, air and soil.