-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

Multi-Scale, Stochastic Fatigue and Fretting in Flexible Marine Risers

Multi-scale, stochastic fatigue and fretting in flexible marine risers

Duration: Sept 2014 to Sept 2018

People:

- Researcher: Patrick Ashton (PhD student)

- Supervisors: Prof. Sean. Leen, Dr. Annette Harte

- Academic Collaborator(s): Prof. Fionn Dunne, Imperial College London

- Technical Team: Mr Bonaventure Kennedy, Mr Pat Kelly

- Industrial partners: Wood group Kenny, Bakaert

- Funding source: Irish Research Council

Summary:

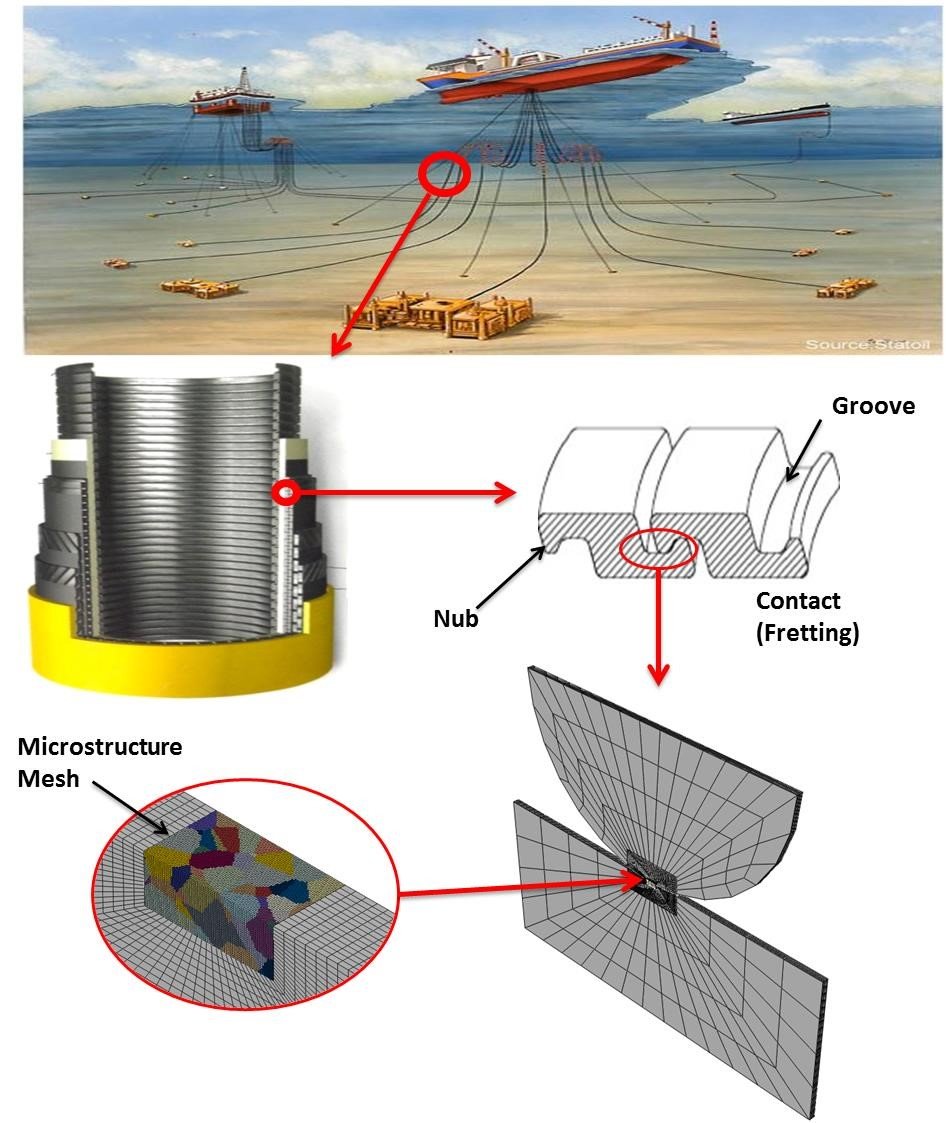

Fatigue is a gradual damage mechanism due to repeated cyclic loading of a structure. Fatigue is the key life limiting factor for marine risers. Flexible marine risers serve the purpose of transporting hydrocarbons from a subsea well to a floating production vessel. Riser systems are subject to complex dynamic loading due to stochastic wave, wind, and current conditions. As a result, it is extremely challenging to accurately predict the service life of marine risers. Fretting fatigue and wear of these components is particularly difficult to predict. Fretting is surface damage caused by small amplitude motion between two contact surfaces. Flexible risers are susceptible to fretting fatigue due to large hydrostatic and hydrocarbon pressures and marine environmental conditions, leading to the potential for premature failure. The pressure armour layers are especially vulnerable to damage from fretting.

The proposed research will develop a combined experimental and computational methodology to measure and predict fatigue crack initiation, wear and surface damage in the steel alloy used for pressure armour layers of flexible marine risers, as provided by industrial collaborators. The research will investigate the effect of riser material microstructure on fatigue life through crystal plasticity models and micromechanics. Experimental testing will be employed to (i) study the crack nucleation and short crack growth behaviour of the material for identification of modelling parameters and (ii) quantify the surface damage due to wear. The prediction methodology will incorporate the effect of key material microstructure parameters, such as grain size and distribution statistics and the statistics of rough surface contacts (asperities).

Publications:

‘Cyclic crystal plasticity modelling of fatigue with application to fretting’, Proceedings of the 42nd Leeds-Lyon symposium on Tribology, Lyon 2015.

Images

The schematic diagram of research methodology