-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

Development of a low permeability polymer liner for LH2 storage

Duration: Sept 2011 to Sept 2015

People:

- Researcher: Brendan Murray (PhD student NUIG/UCC)

- Supervisors: Prof. Conchúr Ó Brádaigh (UCC), Prof. Sean. Leen

- Academic Collaborator(s): Dr. Christopher Semprimoschnig, ESA/ESTEC Materials Space Evaluation and Radiation Effects Section

- Technical Team: Mr. William Kelly, Mr. Pat Kelly, Mr. Bonaventure Kennedy

- Industrial partners: ÉireComposites Teo., AIRBUS Defence & Space

- Funding source: Irish Research Council (IRC), Networking/Partnering Initiative (NPI) with the European Space Agency (ESA), ESA ITI Funding and the Irish Centre for Composites Research (ICOMP)

Summary:

COPVs store highly permeating fuels at high pressures under cryogenic conditions making them an integral part of propulsion systems, breathing systems and specialised research and analysis equipment aboard rockets, satellites and spacecraft. COPVs consists of two distinct layers, an outer fibre overwrap that absorbs the stresses generated by the containment of the high pressure fuel within and a thin inner liner which contains the fuel and limits permeation through the tank wall. Traditionally the thin inner liner has been formed from titanium or aluminium alloys but the current project aims to replace this with a polymer material in an effort to reduce costs through innovative design.

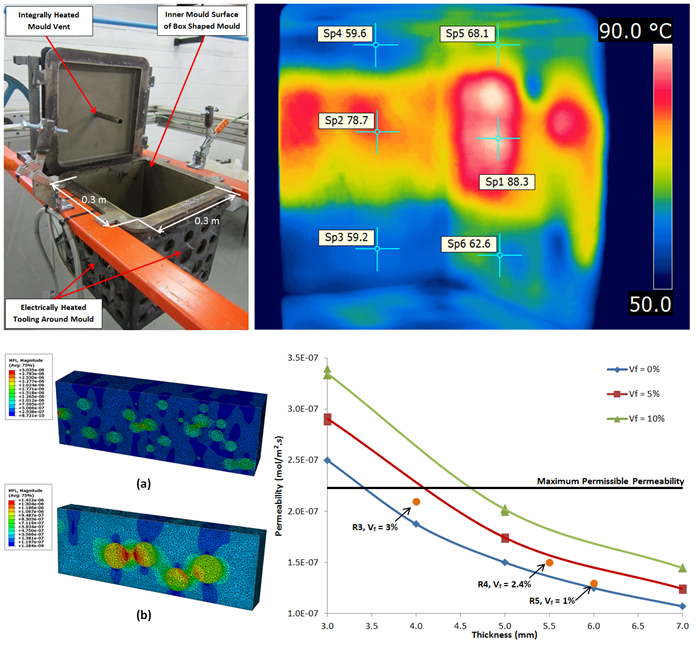

Polymers are a low cost, low weight, and easy to handle material with low permeability properties and a high resistance to chemical attack ensuring good compatibility with highly permeating fuels. The research conducted here focuses on the production of polymer liners using rotational moulding techniques, coupled with laser assisted tape placement of a CF/PEEK composite overwrap onto the liner surface. Topics investigated include polymer liner permeability, the effects of void contents on permeation, process condition effects testing and an assessment of cracking due to thermal cycling in cryogenic environments.

Publications:

- Murray B.R., Leen S.B., Ó Brádaigh C.M. Void distributions and permeability prediction for rotationally moulded polymers. Journal of Materials: Design and Applications. vol. 229, no. 5, 403-418, 2015.

- Murray B.R., Leen S.B., Semprimoschnig C., Ó Brádaigh C.M. Rotational Moulding of Polymer Liners for Composite Overwrapped Pressure Vessels for Cryogenic Fuel Storage Applications. The 12th International Symposium on Materials in the Space Environment, ISMSE12, Noordwijk, the Netherlands, 2012.

- Murray B.R., Leen S.B., Ó Brádaigh C.M. A study of air void formations in a modified rotational moulding process for COPV liners in hydrogen fuel tanks. 29th International Manufacturing Conference, IMC29, Belfast, Northern Ireland, 2012.

Images:

Images showing (a) the integrally heated rotomoulding tooling along with (b) thermal images of hot spots in the tooling and (c) finite element models of void distributions and (d) their effects on permeability with thickness.