-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

Digitalisation of Manufacturing Processes

Diploma in Digitalisation of Manufacturing Processes

Centre for Adult Learning and Professional Development- Title of Award

- Diploma

- Course Code

- DMP1

- Average Intake

- 25

- Delivery

- Blended Learning

- NFQ

- 8

- Award Type

- Minor

- Next Intake

- September 2026

- Duration

- 1 year, part-time

- ECTS Weighting

- 30

Why Choose This Course?

Course Information

Through hands-on training and real-world case studies, students will develop the skills needed to operate, manage, and troubleshoot modern manufacturing processes effectively. With a research-led curriculum and strong industry connections, the course ensures students engage with up-to-date practices and insights from professionals actively working in the field.

Students are encouraged to join the course with an industry-based project concept. Participants will learn by developing this project concept by taking modules in Materials Science & Processes, Manufacturing Technology, and Enabling Technologies for Manufacturing.

At the end of the course, students should be able to:

- Identify cases in an industry where digitalisation of manufacturing processes is possible.

- Implement manufacturing using individual components and systems relevant to producing a functional product.

- Extract and analyse real-time data from manufacturing processes.

- Diagnose problems by thinking critically, innovating and collaborating through team-based work.

- Evaluate, through written and oral communication, technical findings concerning material processing systems.

- Value lifelong personal and professional attributes such as communication, interpersonal, analytical, enterprising and problem-solving skills relevant to a vibrant, technologically advanced economies.

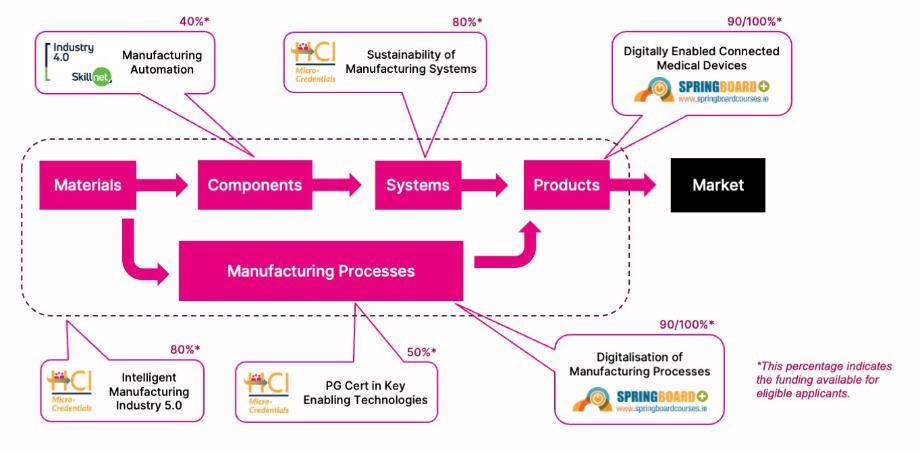

The Manufacturing Process

The manufacturing process involves transforming materials into functional components, which are assembled through sustainable, intelligent, manufacturing systems into products. These products are designed to meet specific market needs. Our new advanced manufacturing diplomas respond to employee skills needs at every stage of this process. See the chart below for an overview of related courses and how they align within the overall manufacturing process.

This course consists of three 10 ECTS modules:

- Materials Science & Processes with Project

This module is on the science of materials, from the small (atomic/nano level) through the micro-scale (grains, crystals, fibres etc.) to the macro or large scale (components, devices, etc.). The learner undertakes a project in materials science which includes the consideration of Atomic Bonding; Structure of Materials; Imperfections in Crystalline Solids; Diffusion; Phase Diagrams; Mechanical Properties of Materials; Failure Mechanisms & Corrosion; Processing of Materials – Polymers, Ceramics and Metals.

- Manufacturing Technology with Project

This course describes how manufacturing processes are used to shape and form materials in modern manufacturing. The materials that are covered include metals, ceramics, semiconductors, polymers, and composite materials. The processes that are included are based on solidification, particulate processing, metal forming, material removal, joining, assembly and surface processing. - Enabling (laser) Manufacturing Technologies with Project

This course describes how a key enabling technology, such as photonics, can be used to transform modern manufacturing. The module describes how laser light is generated and delivered to the workpiece. The laser material interaction is then described for material modification, removal and assembly.

NB: You can take the modules listed above as individual standalone micro-credentials. Please see related courses section at the bottom of the webpage.

Each module features a substantial workplace project component, and students are encouraged to join the course with an industry-based project concept. This approach provides valuable opportunities to build transferable skills that can be applied directly in professional settings.

This course offers access to research labs, makerspaces, and advanced microscopy tools, providing hands-on experience with state-of-the-art systems to enhance learning and job readiness.

The identified career pathways specific to this course include:

- Manufacturing Engineer

- Process Engineer

- Quality Control Specialist

- Industrial Engineer

Dr Adam Collins

Lecturer, School of Natural Sciences, Physics

Dr Gerard O'Connor

Personal Professor, School of Natural Sciences, Physics

The course is delivered part-time through a blended learning approach. Learners will be provided with online materials for each module, specifically developed for independent study. These will be complemented by recommended readings and interactive resources where relevant. In-person attendance is required for approximately 10 hours per module, typically scheduled on Saturdays.

Assessment is carried out through a combination of assignments, written examinations, and, where applicable, practical laboratory work. Examinations are scheduled at the end of each semester, and each module is assessed individually.

If you do not meet the standard entry criteria for this course, you may gain entry through our Recognition of Prior Learning (RPL) policy. Applicants may also be able to earn module exemptions based on their prior learning. Find out more here.

Job readiness is integrated across all modules through group work, problem-solving assignments, conflict resolution discussions, and leadership opportunities in team projects.

Experiential learning, including immersion in labs and opportunities for work-based projects, helps learners develop essential transversal skills such as teamwork, communication, creativity and innovation.

Accreditations & Awards

Meet our Employers

Entry Requirements and Fees

Applicants should have a Diploma at NFQ Level 7 of 90 ECTS minimum, in a Science, Engineering or Technical area, or otherwise prove that they satisfy the modules' prerequisites as listed in the course outline section.

Entry requirements for part-time students can be found here (i.e. Age, English language requirements, etc.).

This course is funded through Springboard+, you can apply for this course here.

NB: Applicants should have a Diploma at NFQ Level 7 of 90 ECTs minimum, in a Science, Engineering or Technical area, or otherwise prove that they satisfy the prerequisites of each of the modules as listed in the course outline section.

Fees for Academic Year 2026/27

| Course Type | Year | EU Tuition | Student Contribution | Non-EU Tuition | Levy | Total Fee | Total EU Fee | Total Non-EU Fee |

|---|---|---|---|---|---|---|---|---|

| UG Diploma | 1 | €2,720 | €3,320 | €- | €2,720 | €3,320 |

Course Administrator

Tel: 091 493909

Email: sciencetech@universityofgalway.ie

Why University of Galway?

World renowned research led university nestled in the vibrant heart of Galway city on Ireland's scenic West Coast.

Downloads

Meet Our Alumni

Introduction

The Diploma in Digitisation of Manufacturing Processes is designed to prepare students for the evolving demands of the manufacturing industry by focusing on the digitalisation of production processes. Learners will gain a solid foundation in materials processing with an emphasis on digitalisation, combining theoretical knowledge with practical application.

This course is funded by Springboard+.