-

Courses

Courses

Choosing a course is one of the most important decisions you'll ever make! View our courses and see what our students and lecturers have to say about the courses you are interested in at the links below.

-

University Life

University Life

Each year more than 4,000 choose University of Galway as their University of choice. Find out what life at University of Galway is all about here.

-

About University of Galway

About University of Galway

Since 1845, University of Galway has been sharing the highest quality teaching and research with Ireland and the world. Find out what makes our University so special – from our distinguished history to the latest news and campus developments.

-

Colleges & Schools

Colleges & Schools

University of Galway has earned international recognition as a research-led university with a commitment to top quality teaching across a range of key areas of expertise.

-

Research & Innovation

Research & Innovation

University of Galway’s vibrant research community take on some of the most pressing challenges of our times.

-

Business & Industry

Guiding Breakthrough Research at University of Galway

We explore and facilitate commercial opportunities for the research community at University of Galway, as well as facilitating industry partnership.

-

Alumni & Friends

Alumni & Friends

There are 128,000 University of Galway alumni worldwide. Stay connected to your alumni community! Join our social networks and update your details online.

-

Community Engagement

Community Engagement

At University of Galway, we believe that the best learning takes place when you apply what you learn in a real world context. That's why many of our courses include work placements or community projects.

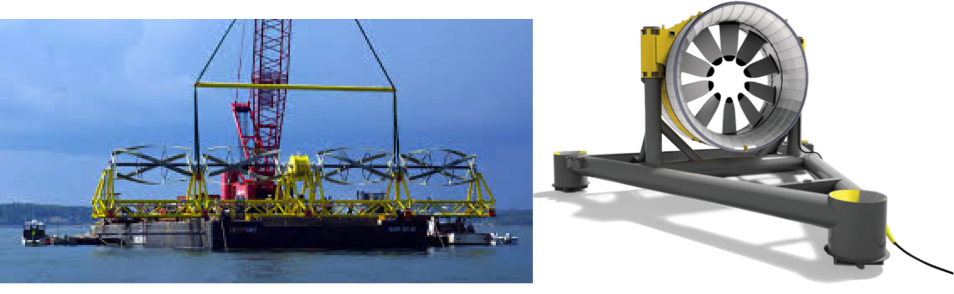

OpenHydro

OpenHydro

Funded by:

Science Foundation Ireland through the National Centre for Marine and Renewable Energy Ireland(MaREI) (Grant No. 12/RC/2302).

Description:

This paper describes the setup and some results of an accelerated life testing study of a tidal turbine blade attachment, which involved high-cycle fatigue testing of a tidal turbine subsystem at the Large Structure Laboratory of the National University of Ireland Galway (NUI Galway). Tidal turbines are in an early stage of development, which implies that there is no standard design and many different approaches are emerging in the market. The subsystem described in this paper is a 3/8 scaled down part of a 10-blade hubless turbine, developed by OpenHydro, a company specialising in the design, manufacture, installation, and maintenance of marine turbines generating renewable energy from tidal streams. The subsystem consists of a blade and a sector of the rotating ring. The sample was installed on an existing 10 m × 6 m × 6 m reconfigurable test frame and was loaded with a servo-hydraulic actuator controlled by an advanced software system, which allowed for an accurate sinusoidal load-controlled high-cycle fatigue test. The sample was loaded at four different levels to accumulate damage representative of a typical tidal turbine deployment life. The main objective of the test was to analyse the structural behaviour of the attachment system solution (blade-rotating ring) under fatigue load, particularly the internal structural welds, and to validate previously developed numerical models. To address all the requirements and to obtain valuable data, a large experimental test was set up. A total of 110 channels in a multi-channel data acquisition system were used to simultaneously acquire strain, displacement, and load data. Accurate measurements of temporal deformations and movement in a 3D field at the rear side of the ring were also acquired using a Digital Image Correlationsystem. The mechanism of failure was expected to be fatigue crack propagationat locations pre-determined in a structural analysis of the system.

Testimonial:

According to Declan Gavigan, R&D Manager, OpenHydro:

"Our collaborative research activities within Dr Goggins’s team in MaREI have provided us with access to world-class research capacity and testing infrastructure that have enabled us to expand our knowledge on how our technology will perform when subjected to extreme underwater conditions, which is critical as our product matures"